Difference between revisions of "ProboStepVX"

From PROBOTIX :: wiki

(→Flexible Design:) |

(→Features:) |

||

| Line 15: | Line 15: | ||

== Features: == | == Features: == | ||

| + | |||

:*Hardware or software selectable step and direction signals | :*Hardware or software selectable step and direction signals | ||

| − | :*Current limit adjustable by potentiometer | + | :*Current limit adjustable by potentiometer |

| − | :*Wide range of motor power ( | + | :*Wide range of motor power (10-42V) |

| − | :*Power (for logic) indicator LED | + | :*Power (for logic) indicator LED |

| − | :* | + | :*3 A, 44 V Output Rating |

| − | :* | + | :*Fixed-offtime PWM blanking circuit reduces ringing |

:*3.0-5.5 V Logic Supply Voltage Range | :*3.0-5.5 V Logic Supply Voltage Range | ||

:*Synchronous Rectification for Low Power Dissipation | :*Synchronous Rectification for Low Power Dissipation | ||

| − | :*Internal UVLO and | + | :*Internal UVLO and Short & Open Circuit Protection |

:*Crossover Current Protection | :*Crossover Current Protection | ||

Revision as of 14:53, 18 September 2013

Model: ProboStep

Contents

[hide]Stepper Motor Microstepping Driver Specs:

- Chopper Current Driver 0.5 - 2.5 Amp Current Limiting

- Dual H-Bridge Configuration

- Full, Half, Quarter, & Eighth Microstepping ?Buffered Step & Direction Lines

- 8V - 32V Power Supply

Description:

The SideStep is a complete microstepping motor driver and control system with a built-in translator. It is designed to operate bipolar stepper motors in full-, half-, quarter-, and eighth-step modes, with output drive capability of 32 V and up to 2.5 A. This driver utilizes the Allegro A3977 chip which includes a fixed off-time current regulator that has the ability to operate in slow-, fast-, or mixed-decay modes. This current-decay control scheme results in reduced audible motor noise, increased step accuracy, and reduced power dissipation. The SideStep is one of the smallest stepper driver boards in its class, making it ideal for incorporating into robots and other industrial control equipment.

Features:

- Hardware or software selectable step and direction signals

- Current limit adjustable by potentiometer

- Wide range of motor power (10-42V)

- Power (for logic) indicator LED

- 3 A, 44 V Output Rating

- Fixed-offtime PWM blanking circuit reduces ringing

- 3.0-5.5 V Logic Supply Voltage Range

- Synchronous Rectification for Low Power Dissipation

- Internal UVLO and Short & Open Circuit Protection

- Crossover Current Protection

Flexible Design:

The ProboStep was designed with flexibility in mind with features including:

- Internal synchronous-rectification control circuitry is provided to improve power 4dissipation during PWM operation.

- Internal circuit protection includes short-circuit and open-circuit protection. Special 4power-up sequencing is not required.

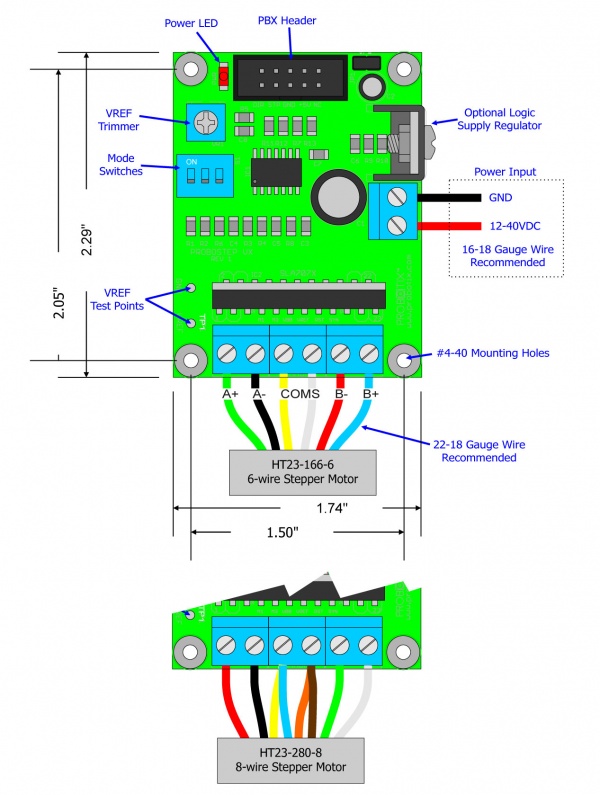

- The logic signals are brought out to a .1" pin header on one side (see Figure 1), allowing for use of an IDC cable to connect your boards. Every other pin on the IDC header is connected to ground, which acts to shield the control signals from noise. Noise in a stepper control system can cause miss stepping, which can damage your equipment, cause 4injury, and ruin your work piece.

- A schmitt trigger IC buffers the high voltage driver from your sensitive parallel port, 4and filters noise.

- Unlike the SideStep, the driver chip, the ProboStep does not have thermal protection, so a heatsink must be used when driving motors at greater than 1 amps.

- An under-voltage lockout circuit protects the A3977 from potential shoot-through currents when the motor supply voltage is applied before the logic supply voltage. All outputs are disabled until the logic supply voltage is above 2.7V; the control logic is 4then able to correctly control the state of the outputs.

- Patented short and open circuit protection.

Unipolar Chopper Drivers:

Unipolar chopper drivers are the simplest form of stepper motor control. A set of four sink drivers control the current to each of the four half-phases of a stepper motor. The circuit includes recirculating diodes and a sense resistor that maintains a feedback voltage proportional to the motor current. The high side of the supply is split out to one side of each half-coil, and the other end of each half-coil is routed to the low-side transistor switches. Motor windings, using a chopper driver, are energized to the full supply level by turning on one set the switching transistors. The sense resistor monitors the linear rise in current until the required level is reached. At this point the switch opens and the current decays until a preset position is reached and the process starts over. This "chopping" effect of the supply is what maintains the correct current voltage to the motor at all times.

Microstepping

Most modern stepper motors have 200 physical steps per revolution meaning they move 360°/200 = 1.8 degrees per step. Chopper drivers are able to further divide down those physical steps by balancing the current of the two phases, in effect "holding" them at different angles between phases. The SideStep can microstep down to 1/8 of a full step, effectively turning the motor into a 200 x 8 = 1600 steps per revolution motors, increasing step accuracy to .225°. Microstepping can also increase rotational smoothness, but the speed of the step pulses has to be multiplied as well. Half-stepping works well for most applications.

Mode 8 uses 70% current ratio between phases, Mode F uses 100% current ratio between phases. Mode F should provide slightly more torque while Mode 8 should give smoother motion.

Diagram

Setting Current Limit

Measure the DC voltage between the Ref Pin and GND, and adjust the trimmer as follows:

VREF = 1.6 x Desired Motor Current 2.5A 4.0V 2.0A 3.2V 1.5A 2.4V 1.0A 1.6V 0.5A 0.8 V

WARNING: Do not exceed 4.0 V unless full stepping!

- Determine the step resolution you wish to use, and set the dip switches according to Figure 2.

- If driving your motors at more than 1.5Amp, install a BGA heat sink over the driver chip. Contact us if you need heat sinks.

- Apply power.

- Connect a voltmeter between the VREF signal and GND and adjust the current trimmer to the desired voltage determined above.

WARNING: Short-term current overdrive will, in general, not harm most motors. But if the motor is connected during this adjustment, excessive heating may occur. Most motors can NOT experience temperatures above 100°C. At these temperatures internal melting and seizure may occur. If you cannot do this quickly, then set the current BEFORE you hook up the motors.

WARNING: Never remove a connection to the stepper motor with power applied. There is a HIGH probability the A3977 IC will be damaged. The A3977 is rated for 35V DC max. The power supply voltage should be limited to ~32V DC to allow for back EMF generated by the stepper.

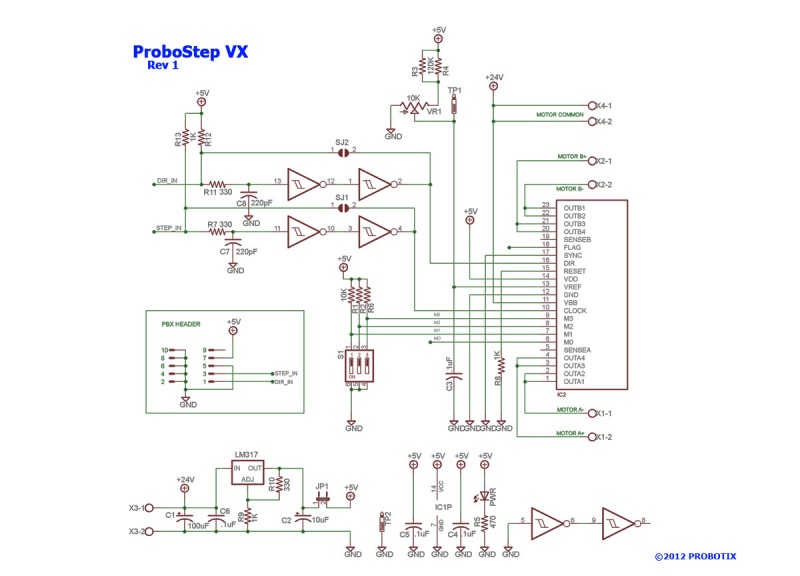

Schematic