Difference between revisions of "Limit Switch Error"

From PROBOTIX :: wiki

m (→Common Causes) |

|||

| (9 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | [[File: Limit switch error.jpg | + | __NOTOC__ |

| + | [[File:Limit switch error.jpg|thumb|Click To Enlarge]] | ||

If you accidentally drive into a limit switch before homing the machine, no need to panic. Follow this procedure: | If you accidentally drive into a limit switch before homing the machine, no need to panic. Follow this procedure: | ||

| − | + | # Click the close button [[File:Close.gif]] in the lower right corner to clear the error. | |

| − | + | # Place a check mark in the box labeled "Override Limits" | |

| − | + | # Click the Machine Power button [[File:Tool_power.gif]] | |

| − | + | # Then you will have one jog maneuver to get off of the affected switch. | |

| − | :#Then you will have one jog maneuver to get off of the affected switch. | + | |

Did you hit the wrong jog button when trying to jog off of the switch? Still no worries, it will error out again, simply follow the steps above again. | Did you hit the wrong jog button when trying to jog off of the switch? Still no worries, it will error out again, simply follow the steps above again. | ||

| − | + | Older software will display errors with joint numbers: | |

| − | Joint 0 = X axis | + | : Joint 0 = X axis |

| − | Joint 1 | + | : Joint 1 = Y axis |

| − | Joint 2 = Z axis | + | : Joint 2 = Z axis |

| + | |||

| + | The Y limit switches are removed for shipping and may not be as tight as the X and Z. If you are tripping the switch when you are nowhere near it, or it's happening randomly, you may be experiencing one of the causes listed below. Try blowing out the lead screws and switches before checking the connections again. If you still have issues contact PROBOTIX and we can send you replacement switches. If you would like spare switches or are not under warranty we offer them on our website. | ||

| + | |||

| + | If you have any bad switches and no replacements, you can temporarily disable the hardware limits in the configuration using the [[LinuxCNC Configurator]]. This will use the switches for homing only. You may need to rearrange working switches so that homing works. Contact support if you need help deciding this. | ||

| + | |||

| + | == Common Causes == | ||

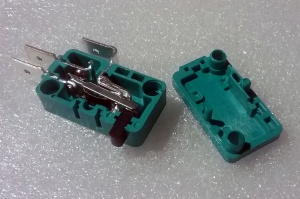

| + | [[File:Limit_switch_apart.jpg|thumb]] | ||

| + | |||

| + | === Dirty Contacts === | ||

| + | The brass contacts inside of the limit switches will oxidize over time and will need to be cleaned or replaced. You can buy new replacement switches | ||

| + | [http://www.probotix.com/CNC-CONTROL-SYSTEMS/ELECTRICAL-COMPONENTS/SWITCHES/GS-LIMIT-SWITCH-SET here]. | ||

| + | |||

| + | === Excessive Vibration === | ||

| + | The switches are spring loaded and can be tripped with excessive vibration from taking to heavy of a cut. | ||

| + | |||

| + | === Loose Cables === | ||

| + | Check all connections, especially the DB-25 cable from the PC to the controller. | ||

| + | |||

| + | === Loose Connectors === | ||

| + | Newer machines use crimp style spade connectors on the limit switches. You can tighten the spade connectors by crimping down the mating surface with moderate pressure from a pair of pliers. | ||

| − | + | === Static Electricity === | |

| + | Some materials, especially certain plastics, create excessive static electricity when cutting. It can be exaggerated when using a shop vac or dust collection system. Running a bare ground wire through the dust collection system can help alleviate this issue. | ||

| − | If | + | === Too Tight === |

| + | If the switch has recently been replaced, it could be screwed down too tightly. This would cause the outer casing to squeeze the spring inside effectively holding it in place. | ||

Latest revision as of 15:19, 16 November 2018

If you accidentally drive into a limit switch before homing the machine, no need to panic. Follow this procedure:

- Click the close button

in the lower right corner to clear the error.

in the lower right corner to clear the error. - Place a check mark in the box labeled "Override Limits"

- Click the Machine Power button

- Then you will have one jog maneuver to get off of the affected switch.

Did you hit the wrong jog button when trying to jog off of the switch? Still no worries, it will error out again, simply follow the steps above again.

Older software will display errors with joint numbers:

- Joint 0 = X axis

- Joint 1 = Y axis

- Joint 2 = Z axis

The Y limit switches are removed for shipping and may not be as tight as the X and Z. If you are tripping the switch when you are nowhere near it, or it's happening randomly, you may be experiencing one of the causes listed below. Try blowing out the lead screws and switches before checking the connections again. If you still have issues contact PROBOTIX and we can send you replacement switches. If you would like spare switches or are not under warranty we offer them on our website.

If you have any bad switches and no replacements, you can temporarily disable the hardware limits in the configuration using the LinuxCNC Configurator. This will use the switches for homing only. You may need to rearrange working switches so that homing works. Contact support if you need help deciding this.

Common Causes

Dirty Contacts

The brass contacts inside of the limit switches will oxidize over time and will need to be cleaned or replaced. You can buy new replacement switches here.

Excessive Vibration

The switches are spring loaded and can be tripped with excessive vibration from taking to heavy of a cut.

Loose Cables

Check all connections, especially the DB-25 cable from the PC to the controller.

Loose Connectors

Newer machines use crimp style spade connectors on the limit switches. You can tighten the spade connectors by crimping down the mating surface with moderate pressure from a pair of pliers.

Static Electricity

Some materials, especially certain plastics, create excessive static electricity when cutting. It can be exaggerated when using a shop vac or dust collection system. Running a bare ground wire through the dust collection system can help alleviate this issue.

Too Tight

If the switch has recently been replaced, it could be screwed down too tightly. This would cause the outer casing to squeeze the spring inside effectively holding it in place.